Process of engineered stone suppliers

Individuals who are not stone experts do not sort out the difference between the two rock types. Both rock types are somewhat different from one another regarding features and output. Quartz is a manmade rock product. On the reverse side, quartzite stone stalks from quartzite quarries. The quartz, situated in clusters, of course, is not suitable for various slab applications from industrial and residential construction projects. For practical use at several jobs, quartz materials need to be converted into Popular engineered stone suppliers. It is the perfect combination of additives, additives, quartz aggregate chips, and unsaturated polyester that assists in creating sensible and ready-to-use engineered stone countertops and countertops. This material puts light on the process for producing engineered quartz and materials utilized to create practical quartz solutions.

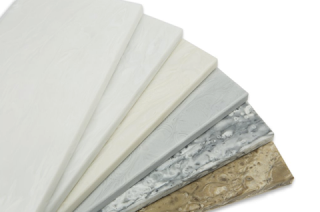

There is no deficiency of engineered quartz slabs out of the competitive global market in the current scenario. In many colors, layouts, and texture variety, quartz slabs are long-lasting and non-porous. To satisfy the increasing demands of domestic and company construction, granite companies generate a wide range of slab alternatives. For making engineered rock slabs, quartz engineers need various raw materials available round in bulk.

Based on physical and mechanical features, calcareous and siliceous aggregates are chosen in the type of sand or grain.

Cosmetic fillers are finely-pulverized stone materials that quartz engineers unite with resin to create bond representatives. Be mindful that mineral fillers might be accessible raw materials.

The coloring agents are metal oxide pigments with a substantial role to play in the custom of rock blending. Coloring agents are crucial for producing infinite options from the visual allure of granite slabs.

Once quartz manufacturers inventory different raw materials, they start the practice of slab making according to the shifting requirements of B2B buyers. The Process for creating engineered stone suppliers quartz stone comprises.

The option of raw quartz materials.

A vacuum and vibration procedure helps in compacting the mixture into slabs.

The vacuum works in 100 minutes at a pressure of about 100 tons.

The slab recovery process assists in gaining stain resistance properties.

Ovens and helps in hastening the recovery procedure.

Comments

Post a Comment